This project focused on solving a fabric delimitation issue in the fabric covers for Flare space panels, the thermoformed ABS extensions that increase sleeping space in Sprinter vans. The challenge was to create a pattern that would conform precisely to a double-curved surface while maintaining clean, consistent tension once upholstered.

The solution: To move the bias of the fabric to the part of the radius where the forces are being applied, allowing for a small amount of stretch in the tightest area where delimitation was occurring.

Exploration:

To address the surface tension issue, I explored two potential patterning solutions, a two-seam and a three-seam configuration. Each redistributed the fabric bias to allow controlled stretch through the high-tension radius of the trim piece.

I created quick mockups of both options, focusing on a single corner to illustrate how the fabric would behave in each scenario before committing to full patternmaking.

After reviewing the results, the two-seam solution provided the best balance of tension and visual cleanliness, so I moved forward with that approach for the first production pattern.

After reviewing the results, the two-seam solution provided the best balance of tension and visual cleanliness, so I moved forward with that approach for the first production pattern.

Draping with adhesive tape:

I began by applying double-sided adhesive tape directly to the panel to achieve a skin-tight surface for draping muslin. Rather than modifying the original one-seam pattern or drafting flat, I chose to drape the form by hand, which proved to be the most efficient way to develop the first accurate pattern.

Ideally, this process could be digitized by unwrapping the 3D CAD model using a SolidWorks plugin like ExactFlat to generate a precise pattern automatically. However, the license cost and limited use cases made that approach impractical.

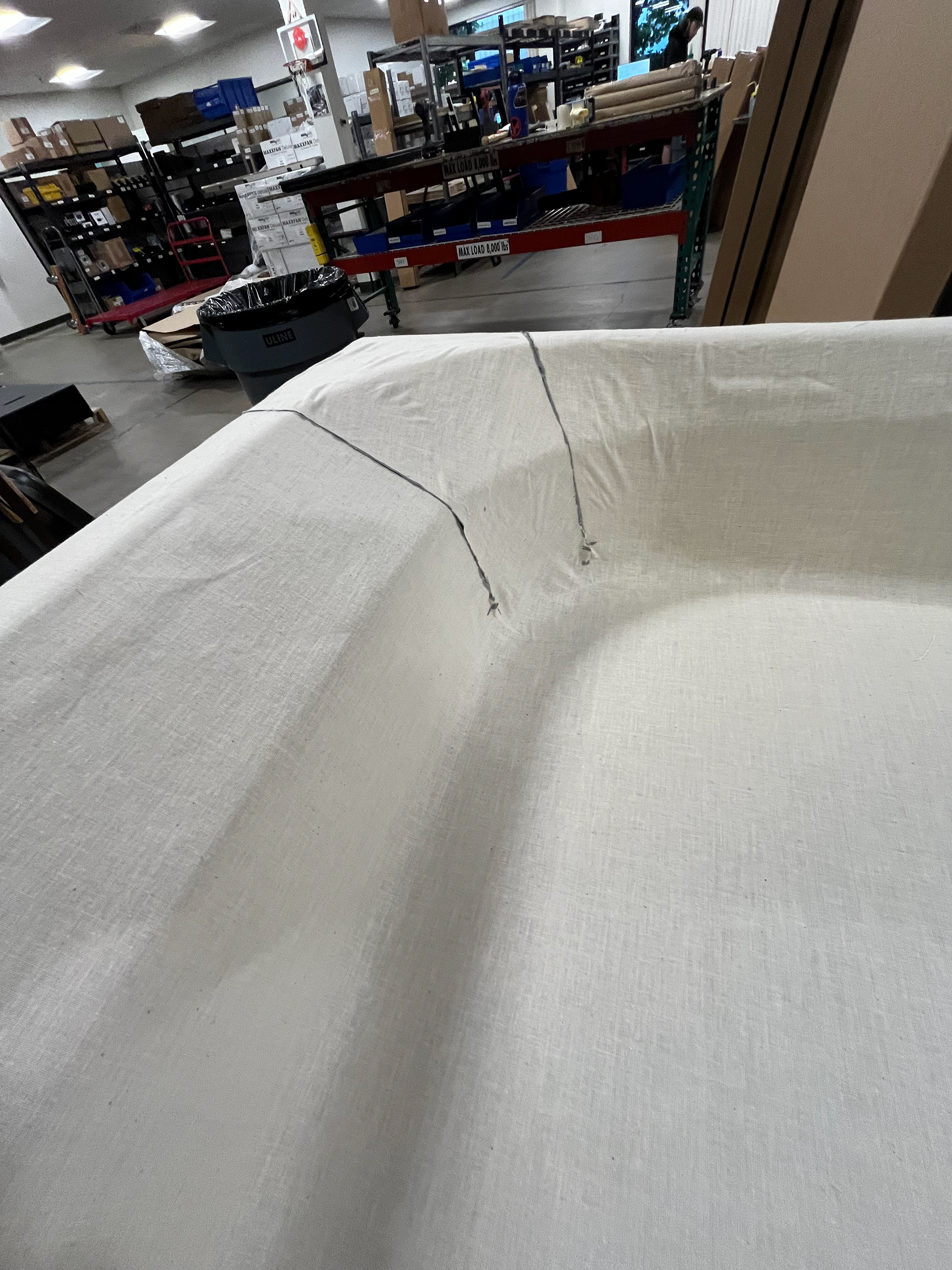

Muslin draping and dart creation:

After applying the tape, I draped muslin over the trim piece using upholstery techniques from my time running that department. I marked the intended seam locations directly on the plastic, then manipulated the fabric into position, creating and refining darts until the material sat flush along the surface.

Transfer to paper and adding seam allouance:

I transferred the finished muslin pattern onto construction paper and added seam allowances. Because several darts were extremely small, I used a ¼-inch seam allowance with a ⅛-inch topstitch.

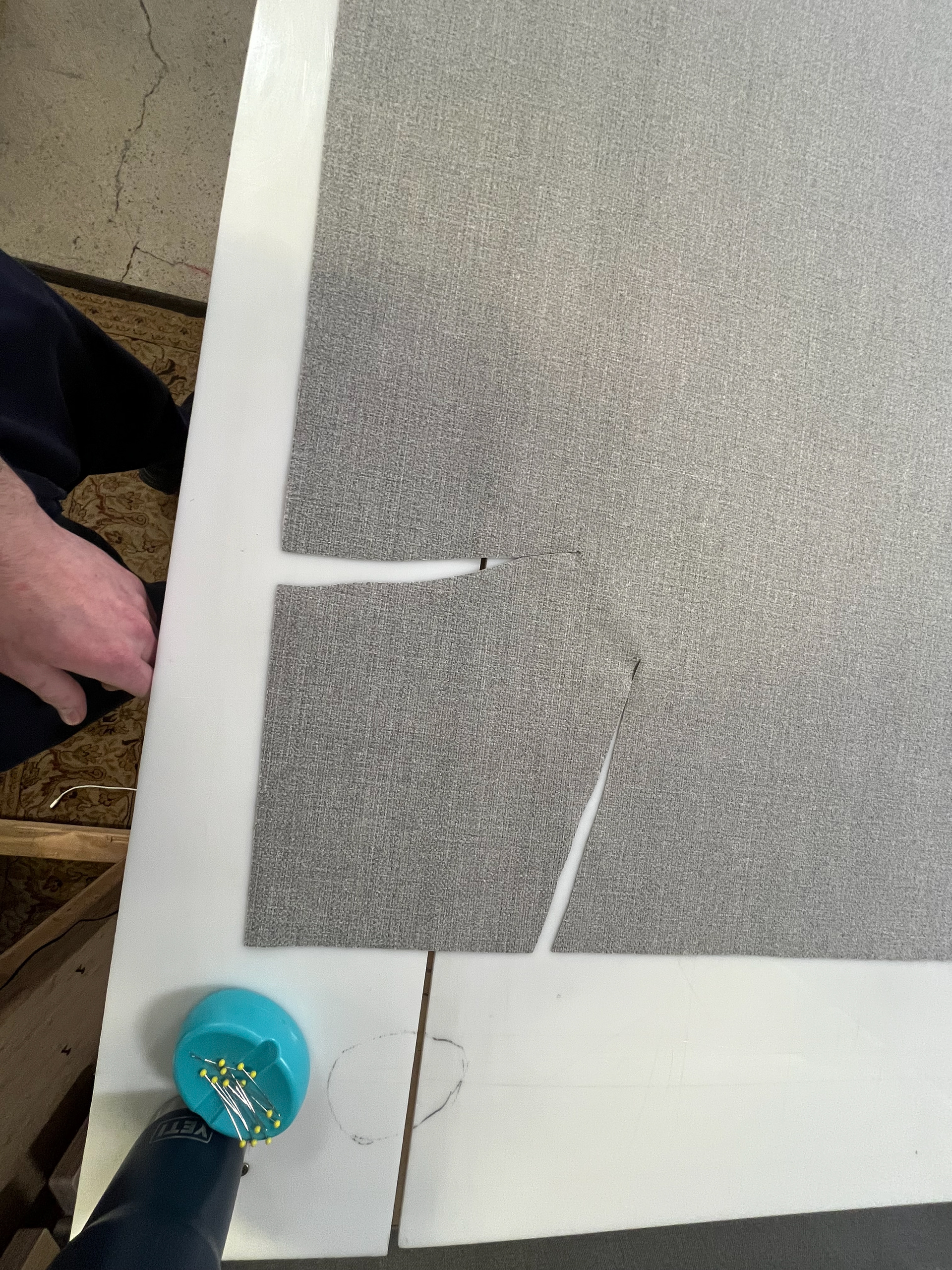

Creating digital patterns:

I created digital patterns to create cut files for outsourcing pattern cutting and to create accurate plastic production patterns for in house use.

The process involved adding reference marks and through lines onto the pattern and using my camera to take photos of the pattern.

I used illustrator to trace the outline and combine all images into a 1:1 scale pattern

The photos on the right show me doing this with the previous 1 seam pattern that I refined in this project, I used the same method to digitize the 2 seam version in this project I just didn't have photos of that.

Final result:

The final step was transferring the pattern onto the woven fabric used for the trim pieces, now with seam allowances included. I sewed the darts and upholstered a single panel to test the fit. The darts aligned perfectly on the first try, confirming that the draping method paired with the adhesive tape produced an accurate pattern. The only adjustment made afterward was widening the side panels slightly to provide more tolerance for wrapping and finishing the edges cleanly.

Conclusion:

The solution performed well and has been implemented in production for several months. The same draping and patterning process was applied to the opposite side with equal success. Since the two trim pieces feature slightly different geometries, pattern adjustments from one side couldn’t be mirrored directly, each required its own full draping and refinement process to achieve a perfect fit.