I documented and standardized the in house production process for a complex soft goods sleep system, turning an existing prototype and tech pack into a clear, scalable workflow for production and future outsourcing.

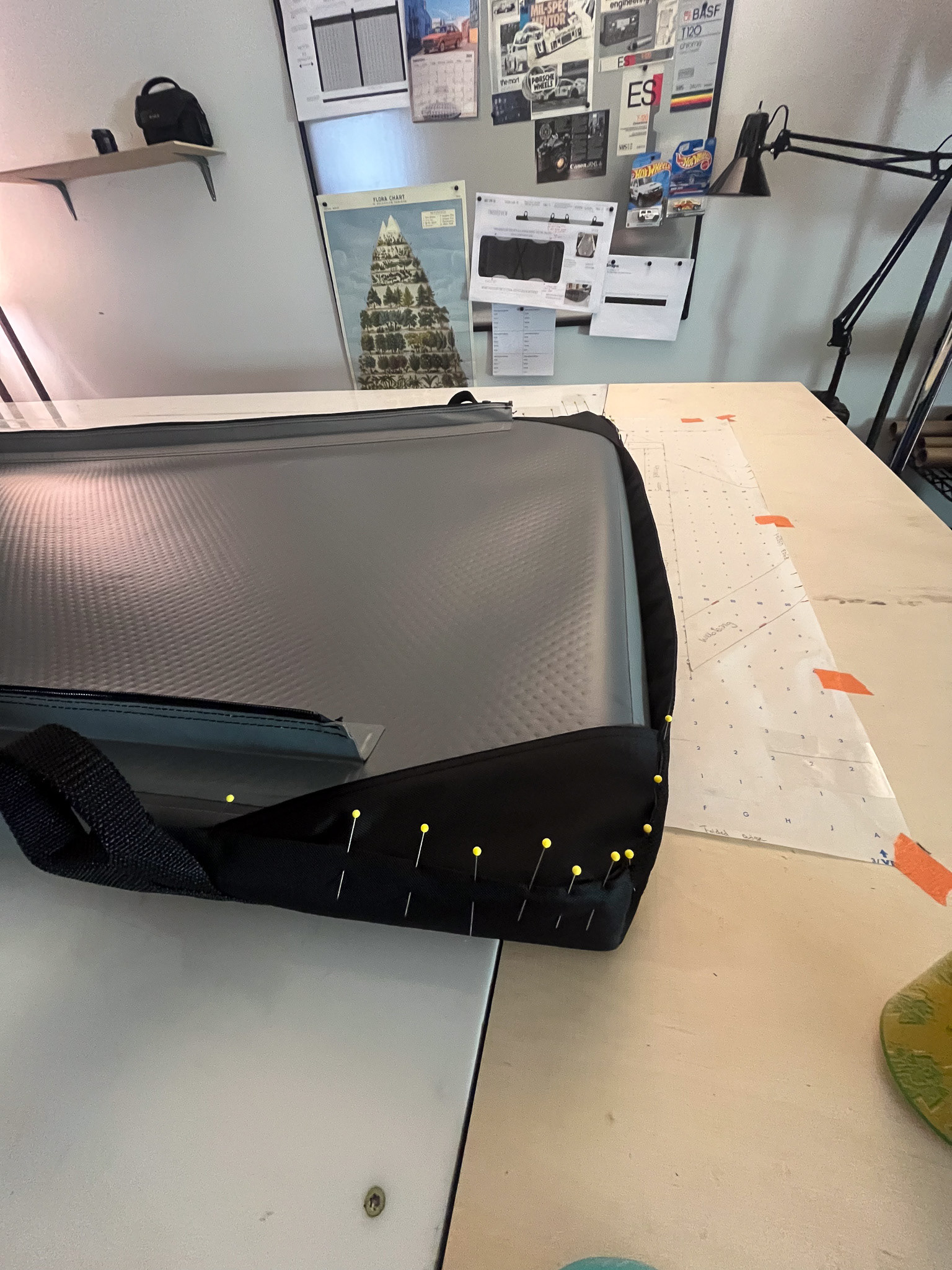

I broke down the original tech pack into clear sub-assemblies, testing and refining each to find the most efficient order of operations. I recorded time studies and material-use data to build accurate production metrics for the management team.

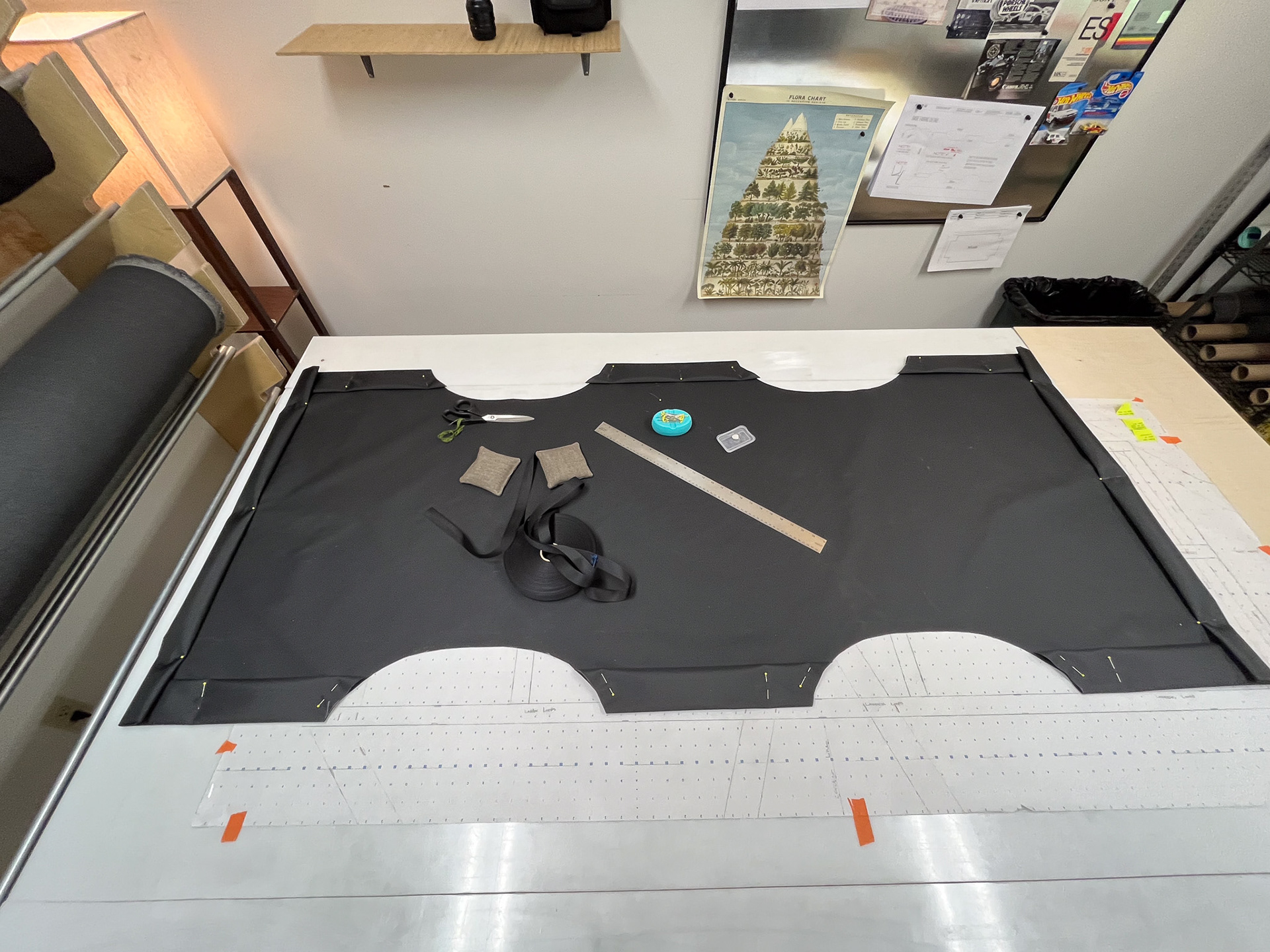

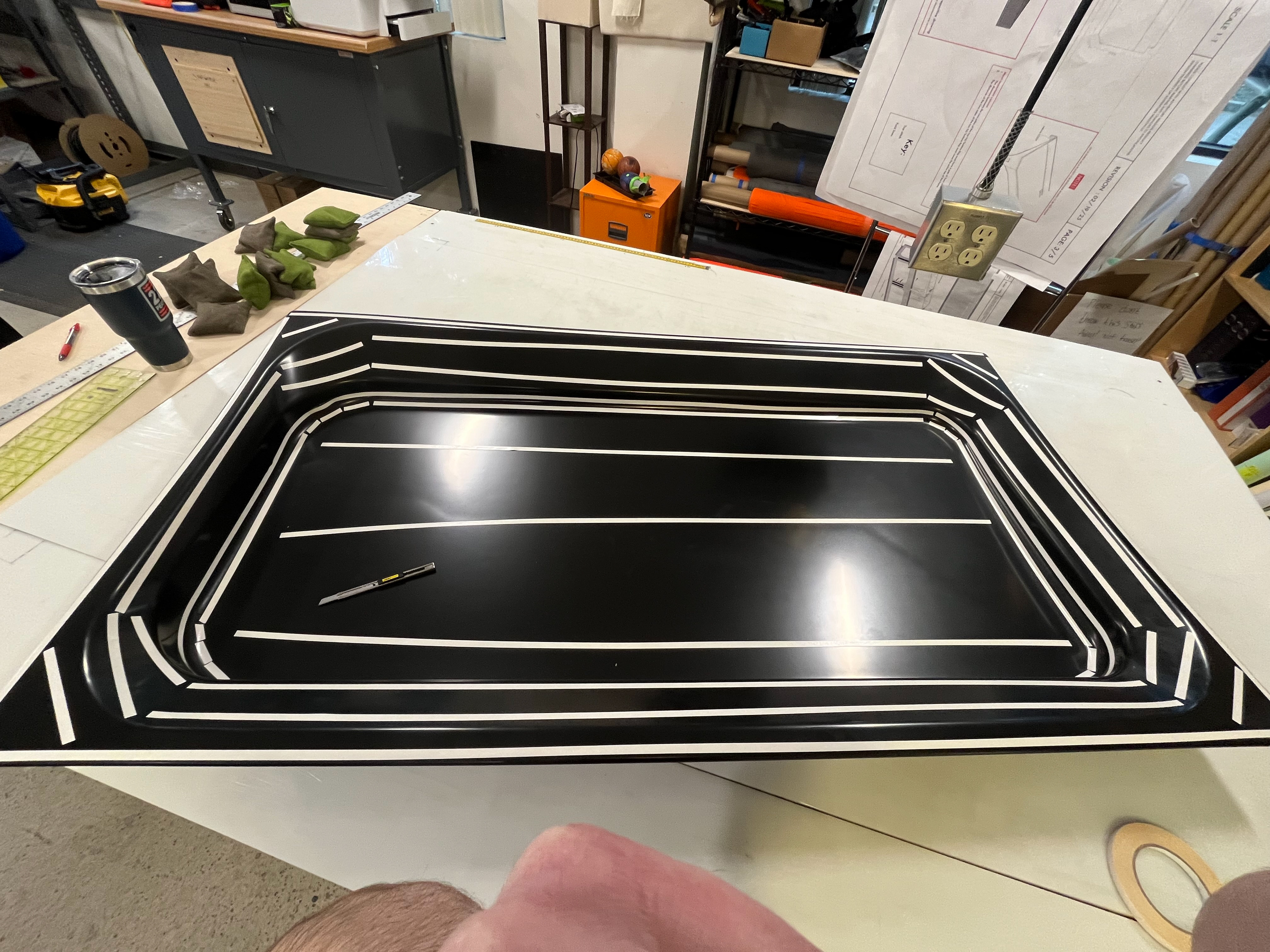

I created production patterns for every sub-assembly that required one, including:

- Main body pattern with layout marks for sub-assembly alignment

- Pocket and elastic patterns

- Webbing loop patterns and jigs for consistent loop lengths

- Corner cap patterns

- 1:1 cut files with alignment marks for laser cutting

Alongside this, I developed visual build instructions covering cutting, sub-assemblies, and final construction to ensure repeatability and clarity.

Over the past year, I’ve been running small-batch production of this product, continuing to refine techniques and improve efficiency. I also updated the original tech pack to reflect final production specs and added additional technical flats to support future third-party manufacturing.